Coffee processing plants

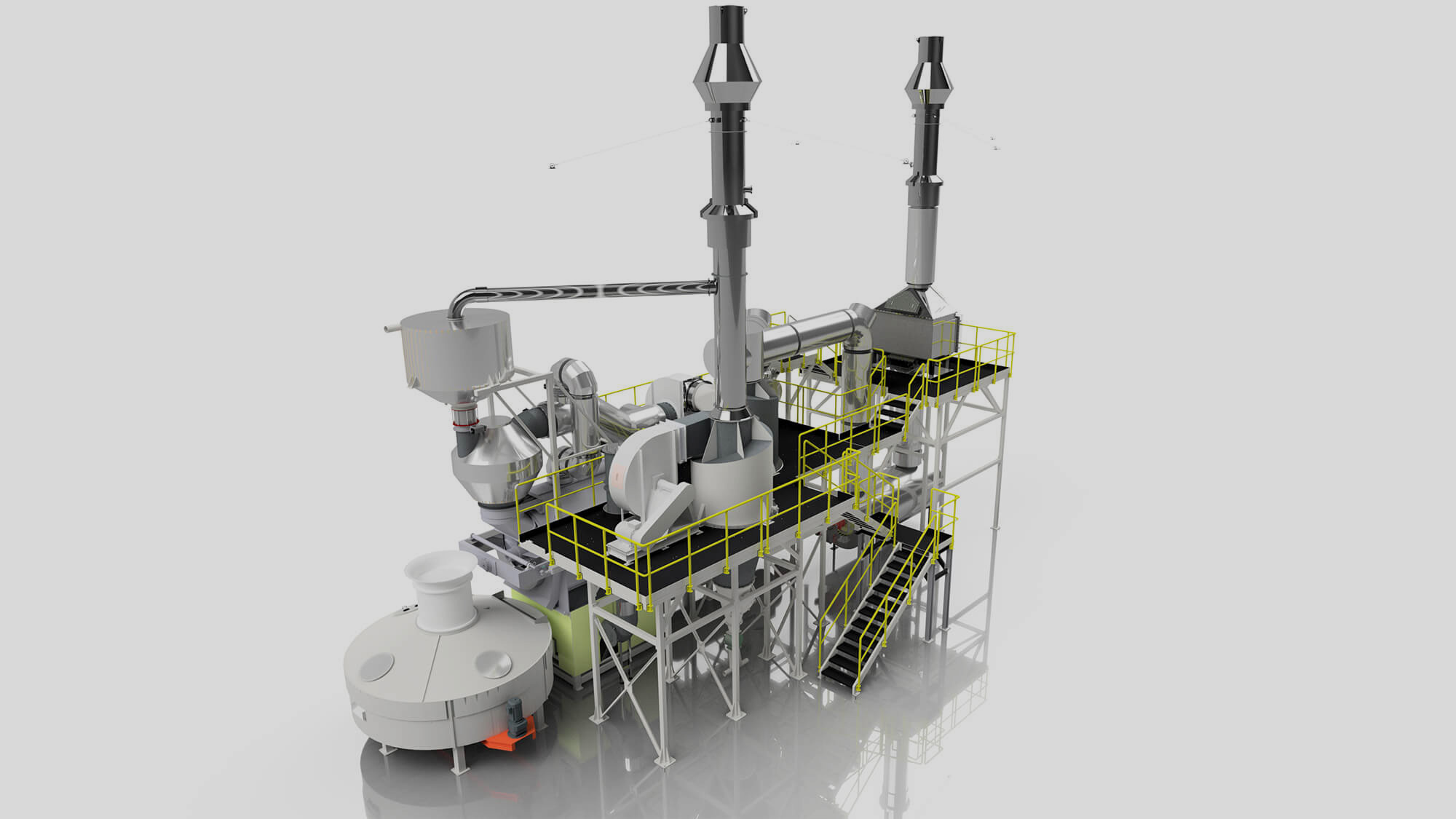

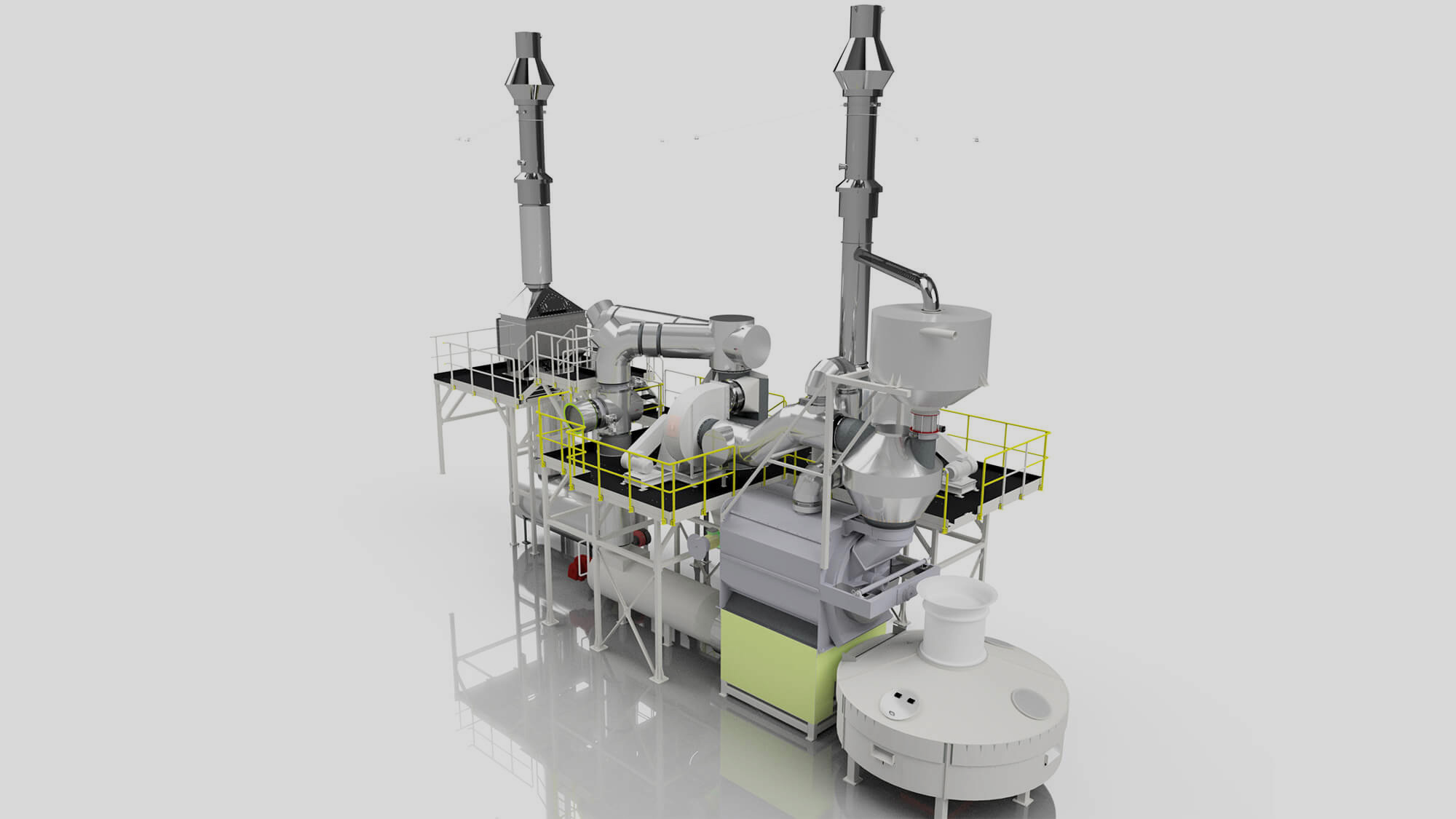

Brambati specialises in coffee production plants and similar types.

We can supply “turnkey” plants, from the reception of green coffee up to feeding packaging machines, through cleaning, storage, weighing, blending, roasting, conveyance (with either traditional mechanical conveyors or the latest generation of slow conveyors), grinding and degassing.

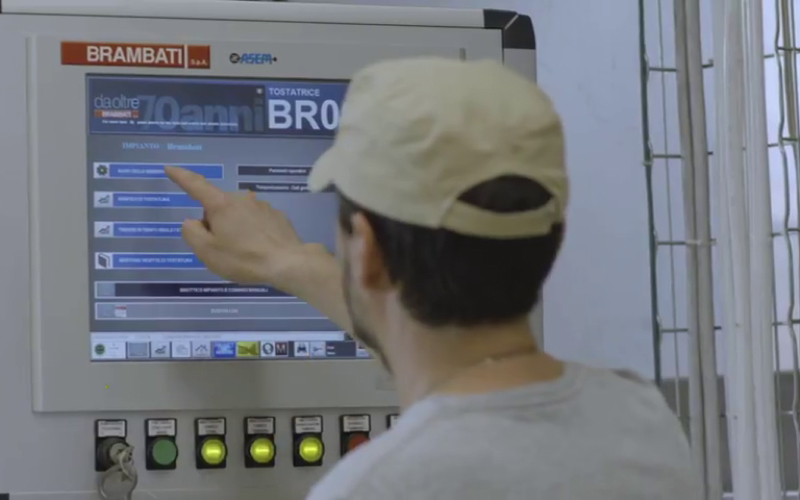

Our roasters come in a variety of sizes, from 5-7.5Kg/batch (20Kg/h.) to 600Kg/batch (3000Kg/h.). They can be the traditional type (KAR or KAR-S models) or with highly automated design (BR models), allowing for complete flexibility in controlling the coffee roasting process, by adapting the roasting features to the different Customer requirements.

Mod. KAR

Mod. KAR-S

Mod. BR

Each of our roasters can be fitted with our ECO afterburner, to control emissions into the atmosphere, and the catalytic converter.

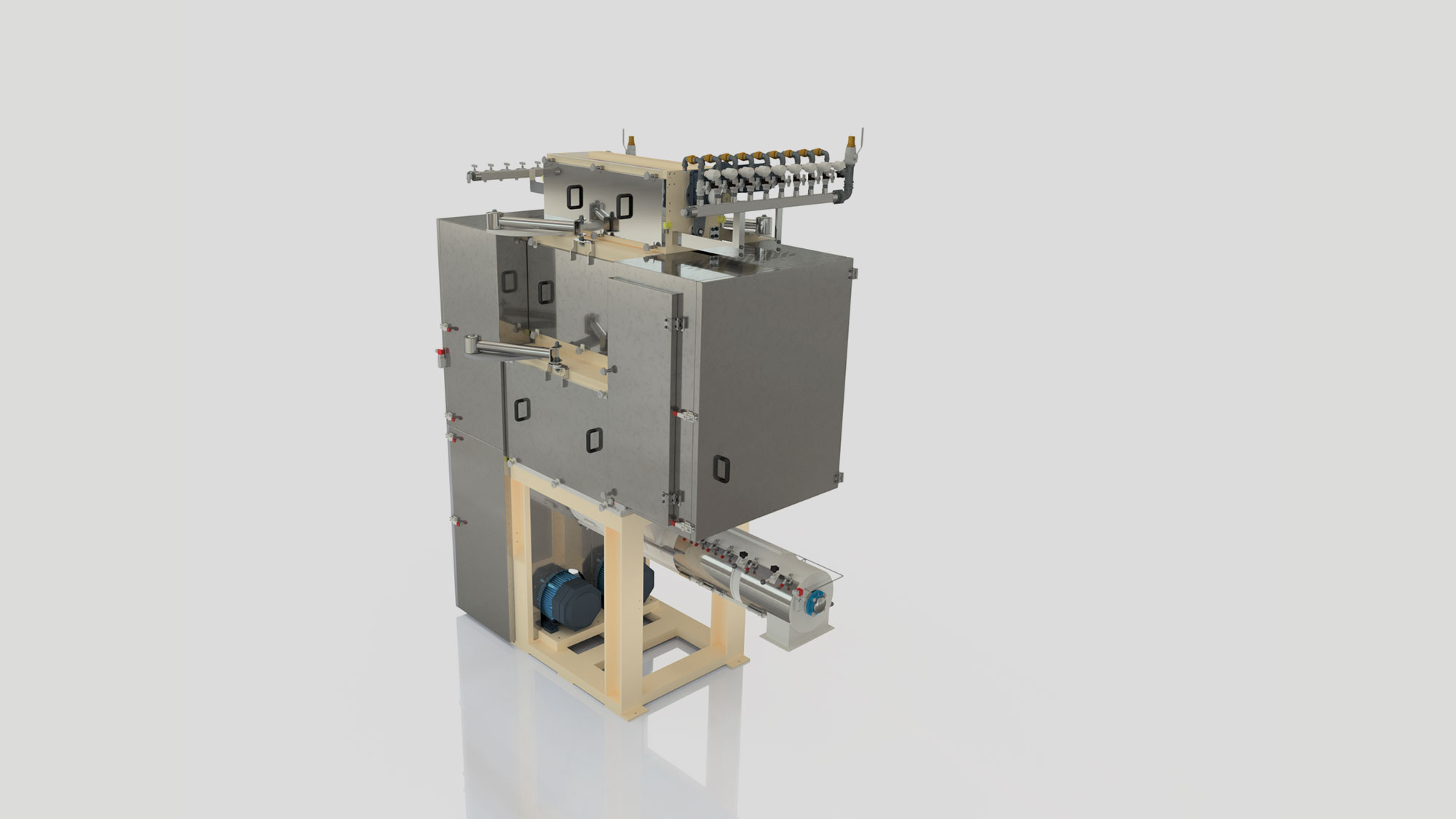

Our grinders can also come in a variety of sizes and types, from the traditional type producing from 100Kg/h to 2500Kg/h for Espresso, Moka and Filter coffee (fully automatic model of the KM series and modular model of the KL/KLL series) and a special type producing from 50Kg/h to 1000Kg/h for Turkish and Greek coffee (fully automatic model of the KMT series and modular model of the KL/KLL series).

Mod. KL3-200 / 600 / 1000 / 1500

Mod. KMT-600 and KMT-1000

Mod. KLL-600 and KLL-1000

Mod. KL3-100 LAB

Since the KL series is modular, models with 600-1000 and 1500 mm rollers can feature single-pass while those with 50-200-600-1000 and 1500 mm rollers can be multiple-pass. This series can also be adapted to grind other types of products such as spices, grains, etc.

We also manufacture a laboratory roaster BRM-200 with max production 200 grs.

Our group also supplies control panels, hardware and software and all our systems can be fully computerised and automated.